Robert W. Yokl, Vice President/COO, SVAH Solutions

One of my company’s most popular podcasts over the past 11 years is “It Wasn’t Raining When Noah Built His Ark.” Whether you are a believer of this story or not, it is still a strong metaphor for where we need to be with our healthcare savings, quality, and sustainability programs. The whole premise is that Noah, foreseeing the coming storm, was being proactive in building his ark and gathering all the animals and succeeded in his quest before the storm hit.

Look to Proactively Develop NewSavings Avenues Before the Storm Arrives Versus Haphazardly Attacking Costs During a Crisis

As a value analysis or supply chain leader, you must be thinking about areas in which you can be proactively developing systems, methods, and reporting, as opposed to quickly and haphazardly trying to reduce costs while in crisis mode. The worst place to be is in crisis mode, as you are under extreme pressure to deliver results. In most cases, because of the rush to put savings on the board, we inevitably leave big dollars still on the table because we are forced to move on to the next big thing our management wants us to work on. Some of you reading this are experiencing this right now and are riding out the storm, while some of you are starting to see the beginning of the storm.

Extreme Budget Tightening and Shoring Up National and Regional GPO Partners is a Great First Step

Things like extreme tightening of non-salary budgets as far as they can go are always a good first measure but that may only work for the first year of a crisis. We are seeing more hospitals switching Group Purchasing Organizations and/or joining regional cooperative groups to further push their price savings to new levels. This is the ultimate goal for a hospital’s group purchasing model, yet once all the volume has been committed and contracts implemented the savings diminish dramatically and trickle in instead of flood in when you first join. The end result is that at best you may be saving 1% to 2% in total supply budget in subsequent years, so this model should be in your plans, but like tightening the budgets you may only get a one-year effect in overall savings. Plus, there is a cost to converting to new contracts and you do not always get the full worth of the promised/guaranteed savings until the second year of converting to a new GPO.

What is the Biggest Bang for the Buck We Should All Be Striving For?

This takes us to two areas that have the biggest potential if calibrated and attacked appropriately: Value analysis and supply utilization. I will make no bones about it, I see these as the biggest savings opportunities by 7% to 18% of total supply budget; 3% to 5% in VA alone and 5% to 15% in supply utilization, and if you combined the two together which is the ultimate model, you will save 7% to 18% of total supply chain budget!

Underused, Underappreciated, and Missing Huge Opportunities

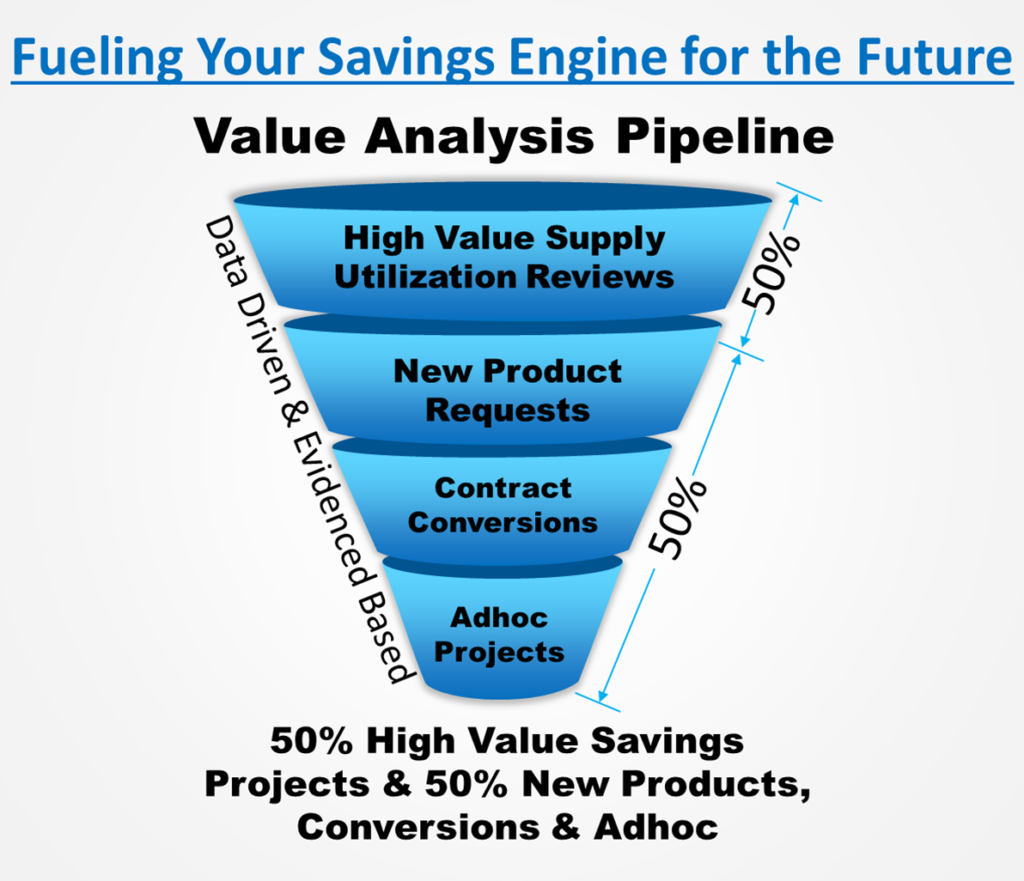

Let’s look at value analysis. If you are looking for big savings from VA, you will need to ascertain how you are using your VA program and whether you are tapping into the true potential of what VA can do for you. If you are only using VA for new products, contract conversions, and the occasional quality or cost problem, then you may only be getting marginal, if any, savings when you net out the cost increase from new products to positive savings implementations. This is wasting the potential of value analysis. You should look to focus at least 50% of your value analysis efforts on proactively attacking your high dollar and high utilization categories, while the other 50% can handle new products and contract conversions. If you want to be successful, then you will move towards this model.

Let’s look at value analysis. If you are looking for big savings from VA, you will need to ascertain how you are using your VA program and whether you are tapping into the true potential of what VA can do for you. If you are only using VA for new products, contract conversions, and the occasional quality or cost problem, then you may only be getting marginal, if any, savings when you net out the cost increase from new products to positive savings implementations. This is wasting the potential of value analysis. You should look to focus at least 50% of your value analysis efforts on proactively attacking your high dollar and high utilization categories, while the other 50% can handle new products and contract conversions. If you want to be successful, then you will move towards this model.

When Are We Going to Learn that We Need to Throw a Blanket Over Our Total Costs to See All and Know All at Any Point in Time?

Now, let’s look at supply utilization management. Supply utilization management in concept is really throwing a blanket over all of your “Total Cost of Products” and tracking these using a volume centric methodology (activity-based costing) to show you the highs, lows, and mid-ranges of your supply chain monthly, quarterly, and by fiscal year. As we always say, supply chain costs are always a moving target but with supply utilization this levels the playing field on volume fluctuations. This then tells you which products/categories are running high and need to be addressed by value analysis, standardization, or perhaps a new contract. Simple, right? From there, we use our supply utilization reporting to power the value analysis engine. Where are we getting 50% of the new high value analysis candidates that are 80% to 90% supply savings winners every time? From supply utilization reporting!

Before, During, and After Should Be Important to Everyone in Supply Chain

Without supply utilization management, we may think that we just improved our price position by 12% on a contract and projected out big savings based on the past 12 months of spend. But was that last 12 months on the upswing, downswing, or something else? Was it at a fiscal year high, low, or mid-range level? If we implement a 12% savings on a category and the category was already starting to increase costs by 15% every fiscal year, then the 12% savings in the base 12-month projection period does not mean much. The hospital will still be faced with an ongoing cost increase but may not revisit this area because they think they saved 12%, when in fact the costs are still rising. We can no longer have this occurring without contracting, sourcing, and value analysis knowing.

Save Big Now, Not Later, When It Comes to the Next Biggest Bang for the Buck

There is an adage in healthcare that I have heard many times from supply chain directors, CFOs and VPs, and that is to focus on the biggest bang for the buck. My goal with this article is to spell out the next biggest bangs for the buck, or next generation of savings that you should not only plan for but simultaneously work on while you are still joining that regional cooperative, GPO, or other supply chain initiatives. The opportunities are there now to start to plan out and add new elements to programs that you have in place to be more proactive in gaining the next levels of big supply chain savings.