Healthcare Supply Chain Expense Savings Opportunities Could Be Easier and Better Than You Think If You Know Where You Stand

“While we have seen a stabilization in operating margins over the past several months, the trendline continues to show that hospitals will be in a tough spot financially for the foreseeable future,” said Erik Swanson of KaufmanHall. “With future COVID surges possible and challenging financial months ahead for hospitals, managing cash on hand will be critical to weathering the storm.” KaufmanHall considers this financial uncertainty as “the new normal” for healthcare organizations for the foreseeable future. Are you ready for this challenge?

No Money – No Mission: It’s Just That Simple

Despite these dire predictions, we frequently hear supply chain professionals talking about their succession, resilience, or sustainability projects, but none of these things are possible without your healthcare organization having a healthy bottom line. This can only happen with supply chain’s help to reduce 30% of their hospital, system, or IDN’s budget which has increased by 21.9% from 2021 to 2022. We know this is getting harder to do because your price savings are disappearing and your standardization is substantially completed. However, there are still millions to be saved in wasteful and inefficient consumption if you know how and where to look for them. That’s why new supply chain expense savings opportunities could actually be much easier and better than you think if you know where you stand.

Are You Flying Blind Or Do You Know Where You Stand?

We are often asked how a healthcare supply chain organization can get better than just good. Our answer is always to employ key performance indicators (KPIs) to quantify, qualify, and measure your supply chain performance over time. This way your supply chain team has goals to shoot for, milestones to meet, and insights into their operations. On an operational level, KPIs provide a window into your supply chain operations (i.e., expenses, service quality, logistics, etc.) to determine whether or not your supply chain is on track or needs improvement.

Most progressive healthcare organizations are applying KPIs (or quantifiable measurements of performance over time for a specific purpose) to highlight aspects of their financial, employee, productivity, and customer performance, such as, average treatment cost, claim denial rate, bed occupancy rate, etc., to create a culture of success. It should be clear that without KPIs your healthcare organization is flying blind! Yes, we could make this same statement about supply chain management in most hospitals, systems, and IDNs.

Are You Avoiding Blind Spots In Your Supply Chain?

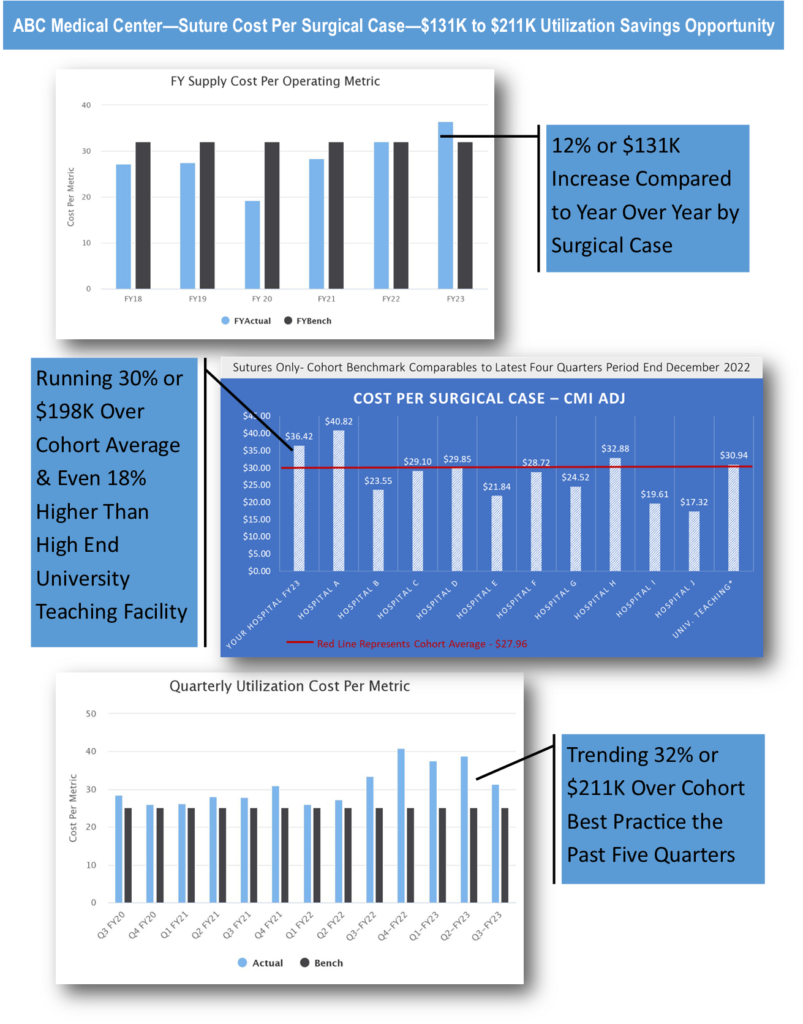

This same KPI success methodology employed by your healthcare organization in other areas of your operations can be applied to supply chain management to avoid blind spots. For you see, with KPIs you are measuring your success versus just setting targets, objectives, or even comparing yourself to peers for even greater success. KPIs can be financial, operational, or functional, and deemed mission critical for your supply chain operations. For instance, on a recent client meeting we were asked to establish “Suture Product KPIs” for their hospital (Figure 1), which resulted in the supply chain and perioperative department being able for the first time to know where they stand on their sutures beyond just price and standardization. This data enabled them to justify a thorough value analysis review to weed out inefficiencies, eliminate waste, and enhance their storage and ordering processes. How else would they know they had over $200K in savings available to them without comparative KPIs?

Figure 1: Sample Supply Chain Labor Comparative KPIs

Refocusing Your Cost Reduction Efforts Could Be Easier and Better Than You Think

Now that your price cost reduction efforts have been stalled due to inflation, stagnation, and vendor push back, saving money is still necessary for your healthcare organization’s survival to continue to reduce your labor and non-labor costs. The only question is how to do it. The answer is always to employ key performance indicators to measure, monitor, and manage your performance. That’s why refocusing your cost reduction efforts could be easier than you think!

| About Robert T. Yokl, Founder & Chief Value Strategist for SVAH Solutions |

|---|

| Robert T. Yokl is President and Chief Value Strategist at SVAH Solutions. He has four decades of experience as a healthcare supply chain manager and consultant, and also is the co-creator of the Clinitrack Value Analysis Software and Utilizer Clinical Utilization Management Dashboard that moves beyond price for even deeper and broader clinical supply utilization savings. Yokl is a member of Bellwether League’s Bellwether Class of 2018. https://www.SVAH-Solutions.com https://www.SavingsValidator.com |

Articles you may like:

If Supply Chain Excellence is Your Top Priority: You Need to Know Where You Stand