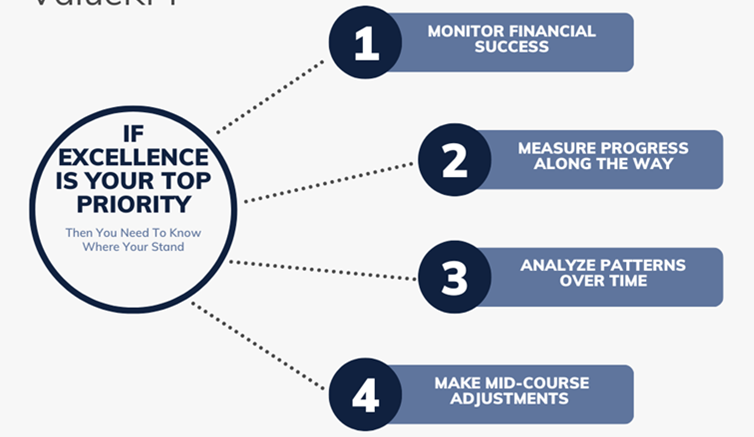

We often assume that our supply chain division, department, or unit is performing at the highest performance levels, but are we really sure? From our experience, we can only be absolutely sure by employing key performance indicators (KPI) to:

1. Monitor Your Financial Success: Are we meeting our savings, budget, and long-range goals? For instance, one of your financial KPIs to determine your financial success could be the annual supply savings/annual supply budget = net savings. We have found that this is a much better measurement for your financial success than savings per contract or initiative, since “net savings” represents what savings really hit your healthcare organization’s bottom line each year.

2. Measure Progress Along The Way: Just the other day, one of our clients asked us to establish a new KPI to ensure that a new freight management company they contract with meets its savings commitment to them. Otherwise, how would they know if the savings milestones that were represented in their vendor’s proposal were achieved?

3. Analyze Patterns Over Time: We just observed a pattern in which one of our client’s instrument repair cost KPIs jumped by 49% or $225,000 in the last calendar year. Naturally, we recommended that our client investigate this change in their instrument repair pattern that has been constant for years.

4. Make Mid-Course Adjustments: How many times have you been promised savings by your GPO or vendors that never happened? Well, too often this is caused by internal operational oversights such as not training medical staff in the use of a new product, service, or technology. The good news is that these issues can be corrected by establishing KPIs that monitor that these savings are happening as planned. This happened when a hospital client of ours was given higher contrast media doses than medically required and squandered the savings that was projected at the start of the new contrast media contract. However, once this problem was detected and corrected the projected savings started flowing again.

As we mentioned in our introduction to this article, it is almost impossible to know how you are doing operationally without having key performance indicators to direct you to areas of improvement or to validate what areas you are best-in-class in. So, if excellence is your priority you need to know where you stand to ensure you are filling your supply chain mission at the highest service and operational levels possible.

| About Robert T. Yokl, Founder & Chief Value Strategist for SVAH Solutions |

|---|

| Robert T. Yokl is President and Chief Value Strategist at SVAH Solutions. He has four decades of experience as a healthcare supply chain manager and consultant, and also is the co-creator of the Clinitrack Value Analysis Software and Utilizer Clinical Utilization Management Dashboard that moves beyond price for even deeper and broader clinical supply utilization savings. Yokl is a member of Bellwether League’s Bellwether Class of 2018. https://www.SVAH-Solutions.com https://www.SavingsValidator.com |

Articles you may like:

Hospital Value Analysis: Simplify, Systemize, and Automate Workflow Processes for Maximum Results

Healthcare Value Analysis: Steps for Achieving Better Results