Diana Berkland, PhD, RN—Vice President, Nursing & Clinical Services, Sanford Health; Erica DeBoer, MA, RN, CCRN-K, CNL- Clinical Nurse Leader, Sanford Health; Tom Harvieux, MSc—Senior Executive Director, Corporate Supply Chain Management, Sanford Health; Andrew Hogan, BSc – Associate Project Manager, Cornerstone Research Group, Burlington, ON

The Importance of Optimizing Urology Catheter Management

Optimal insertion and management of urology catheters is an important component of patient care. Implementation of quality improvement measures have been shown to help reduce variation in healthcare processes and help enhance patient care.1,2 Strategies to promote changes in clinical culture and practice through appropriate urology catheter use, proper catheter insertion and maintenance, and appropriate catheter removal have been recommended by the Centers for Disease Control and Prevention and Agency for Healthcare Research and Quality to improve clinical outcomes such as reducing the incidence of catheter-associated urinary tract infections (CAUTIs).2,3 Standardized processes may also help increase efficiencies in supply chain management by reducing stock keeping units (SKUs) and product waste.4,5

Having recognized the value of a standardized urology catheter practice program, Sanford Health recently implemented an initiative aimed at streamlining urinary catheter use-associated processes and reduction of care variation, while focusing on patient care. Interviews with Sanford staff, representing infection prevention, supply chain management and nursing departments, were conducted to characterize Sanford’s experience with this ongoing initiative.6

Historic Catheter Management at Sanford Health

Sanford Health is an integrated health enterprise that includes 4 major medical centers, 2 large community hospitals, 41 critical access hospitals, and more than 250 clinics spanning 9 states, with its corporate location in Sioux Falls, South Dakota. Across the enterprise, management of urology catheters was historically handled on a site-by-site basis. Within and across centers, various clinical practice guidelines and protocols were originally in place to manage catheter insertion/maintenance and to prevent CAUTI.2,7,8 These guidelines did not call for standardized urology products, and so the availability of products within and across the enterprise differed. Supply chain representatives at Sanford indicated that in many cases, when supplier contracts ended, products were replaced on the basis of the local value analysis process.6 Standardization of products was not present across the enterprise, which led to different practices at different sites; product choices and availability often guided clinical practice.6

Sanford Health is an integrated health enterprise that includes 4 major medical centers, 2 large community hospitals, 41 critical access hospitals, and more than 250 clinics spanning 9 states, with its corporate location in Sioux Falls, South Dakota. Across the enterprise, management of urology catheters was historically handled on a site-by-site basis. Within and across centers, various clinical practice guidelines and protocols were originally in place to manage catheter insertion/maintenance and to prevent CAUTI.2,7,8 These guidelines did not call for standardized urology products, and so the availability of products within and across the enterprise differed. Supply chain representatives at Sanford indicated that in many cases, when supplier contracts ended, products were replaced on the basis of the local value analysis process.6 Standardization of products was not present across the enterprise, which led to different practices at different sites; product choices and availability often guided clinical practice.6

In the past, efforts in urology catheter practices and management of urology products at Sanford Health were handled on a center-by-center basis. These attempts often focused on managing SKUs or revising local urology catheter policies. Sanford recognized the importance of developing consistent urology catheter management policies across the enterprise, and was committed to developing internal practice standards designed with the objective of long-term success and sustainability.

Sanford’s Solution to Urology Catheter Management

In 2016, Sanford began working to establish an enterprise-wide standardized framework for urology catheter management that was intended to address the historic challenges identified above. The goal of the project was to reduce variation in patient care by standardizing both policies and clinical practice within and across centers. If done correctly, this would naturally standardize products across the enterprise. This goal aligned with the strategic direction for Sanford, as it focused on:

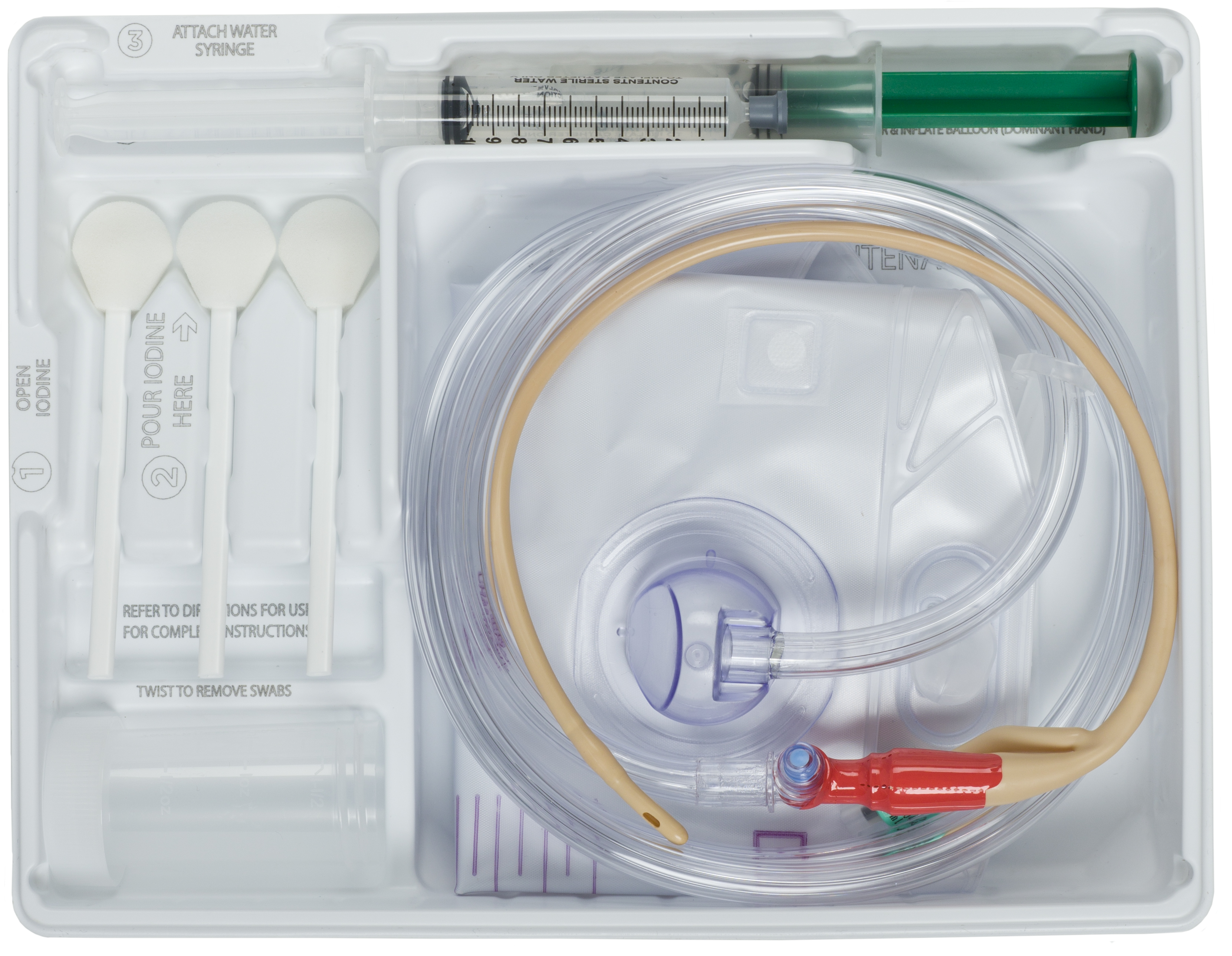

To achieve an evidence-based, reliable catheter insertion and maintenance standardization strategy Sanford sought ways to share knowledge and collaborate with industry partners. Sanford chose to partner with a market leader in urology supplies, Bard Medical (a division of C. R. Bard, Inc.), and implemented the ZERO-IN™ Comprehensive Clinical Solutions Program.9 This program is aligned with the goals Sanford had set for itself, being a data-driven, clinically led initiative which, through product training and education, aims to address key gaps in clinical practice and variations associated with the use of urology catheters. Overall, the ZERO-IN™ Program helped Sanford evolve its culture around policy and product selection at an enterprise-level. It helped promote a change in philosophy, shifting from a situation where products were selected based on local SKU availability, to a situation in which standardized practice patterns help enable a consistent selection of products across centers. This supported the alignment of product availability with institutional clinical standards. Use of Bard products is easily teachable and may help support sustainable practices. Their products, delivery systems, trays, and procedures are designed to aid healthcare professionals through the catheter insertion process while supporting best clinical practice.9 Collectively, these attributes are designed to help minimize practice variation associated with catheter insertion.9

Implementing an Enterprise-wide Policy

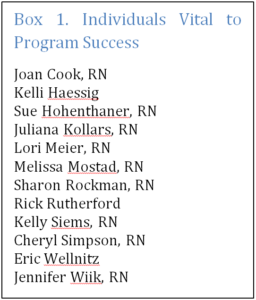

The development and implementation of a standardized urology catheter practice policy required internal collaboration across Sanford Health. This could only be achieved through a cooperative partnership between supply chain, infection prevention, quality control and nursing personnel. Erica DeBoer, a Clinical Nurse Leader at Sanford Health, was dedicated to involving staff across departments, some of whom are acknowledged in Box 1. Ms. DeBoer brought a rich clinical background and trustful relationships with the entire interdisciplinary team. Together, this cross-functional team developed strategies to achieve urology practice standardization, reduce variation in care, and improve clinical practice.

In the early stages of the initiative, and as part of the ZERO-IN™ Program, Sanford and Bard Medical identified gaps in urology catheter practices involving Bard Medical products. This enabled Bard Medical to provide customized product training to Sanford staff. Using this information, Sanford developed a new internal urology catheter management policy to include the entire lifecycle of the catheter, from insertion to removal. This policy was reviewed in detail by Sanford leaders and clinical staff to ensure evidence-based practices were appropriate for facilities across the enterprise. Adherence to the standardized policy developed by Sanford was supported by the ZERO-IN™ Program, which helped Sanford to standardize Bard Medical’s urology products by supporting consistent product selection.

With the finalization of the policy, Sanford communicated the program across the enterprise to ensure that all staff were involved and informed. Communication played a vital role in the successful adoption of this program, as staff embraced the new patient-centered rationale for adopting the new policies and culture. To ensure effective communication, Sanford used a wide range of media including live education sessions, training materials, in-person meetings, teleconferences, team meetings, email communications, and flyer distribution. Nursing teams were critical in coordinating the introduction of the initiative across Sanford.

The successful development and implementation of the standardized urology catheter practice at Sanford was supported by Bard Medical. The product training and education tools provided by Bard Medical helped Sanford identify practice variation gaps and challenges, which was instrumental for Sanford to develop optimal evidence-based policies. During the implementation stage, Bard Medical provided product training as well as on-site staff education for clinical and supply chain personnel, and offered suggestions for product rationalization to support the standardized clinical processes that Sanford was seeking.

The successful development and implementation of the standardized urology catheter practice at Sanford was supported by Bard Medical. The product training and education tools provided by Bard Medical helped Sanford identify practice variation gaps and challenges, which was instrumental for Sanford to develop optimal evidence-based policies. During the implementation stage, Bard Medical provided product training as well as on-site staff education for clinical and supply chain personnel, and offered suggestions for product rationalization to support the standardized clinical processes that Sanford was seeking.

Achieving Standardized Care

It is well accepted that variation reduction is important for the financial well-being of healthcare facilities.10 Further, a single vendor can help improve efficiencies and reduce costs associated with contracting, product ordering, and inventory management.4,5,11 Infection prevention, supply chain, and nursing personnel at Sanford reported that they were able to successfully achieve their goal of creating an enterprise-wide standardized policy for urology catheter practices ranging from insertion, maintenance, removal, and specimen collection.6 Although the policy has only recently been implemented, important benefits are already being observed. These include substantial reductions in the following:

- The number of SKUs, with nearly 74% fewer urology products on the formulary12

- Ninety four percent compliance to the urology product formulary in the initial adoption sites12

- The number of acute care urology supply vendors has lowered from five to one12

- Early evidence of reduction in catheter utilization12

According to the Sanford staff, reducing the number of SKUs has led to benefits from both supply chain and nursing perspectives: (i) Supply chain staff have observed an increase in the efficiency and ease of managing product inventory; (ii) Nursing staff have reported improved clinical knowledge on available products.6 A randomized trial by Keleekai et al, has demonstrated that training and education of nursing staff on appropriate catheter use resulted in improved knowledge, confidence, and skills, which may lead to improvements in clinical practices and patient care.13 A standardized policy and protocol helps nurses make decisions regarding appropriate product use, as fewer products are available. Nursing staff at Sanford have cited the observed benefits of a standardized process in terms of reinforcing the principles and importance of proper aseptic techniques, which may transfer to other areas of care.6

To promote sustainability Sanford will continue to monitor its practices, including:

- Reduced waste resulting from product expiration

- Decreases in available SKUs

- Increased formulary adherence

- Reduction in the number of indwelling catheter days

- Reduction in overall catheter use

- Economic benefits associated with standardization

Although the initiative is still in its early stages and data are not yet finalized, Sanford is hopeful that long-term success and the sustainability of early gains will occur through adherence to the standardized policy and product selections. To ensure this, Sanford is focused on continued communication with regularly scheduled follow-up meetings and calls to keep staff motivated. New staff will consistently receive Bard Medical product training and education through the ZERO-IN™ Program, to help address the challenges of nursing turnover. Patient outcomes will continually be monitored to allow issues that require attention to be addressed. If a nurse requests a unique product, clinical nurses and leadership will evaluate the evidence supporting the requested product to determine whether it should be adopted across the entire enterprise. Any one-off exceptions would require careful consideration to ensure the sustainability of the policies with a focus on enterprise-wide standardization into the future.

The adoption of a standardized policy across a large hospital enterprise was not without its challenges. The largest hurdle was ensuring that staff across all facilities received appropriate product training and education. To overcome this challenge, various means of effective communication were used to reach staff across the hospital system. This was supported by the leadership team.

With the large-scale conversion of available products, some staff were initially hesitant about the newly standardized products. Sanford actively addressed these concerns through staff education and transparent conversations about the rationale behind changes in product selections and patient care implications. Product training and education sessions allowed staff to handle the new products and observe their features and benefits. The personnel from Bard Medical played a key role in answering questions and handling these concerns, working to train and support staff with the new products.

Future Perspectives

Working in close partnership with Bard Medical as one of their pilot accounts, Sanford’s executive team successfully made use of the ZERO-IN™ Program. Since Sanford’s development of a standardized, enterprise-wide, urology catheter practice policy, there has been a reduction in both product and practice variation at Sanford Health.6 Although there are limitations associated with this report, for instance the success seen by Sanford reflects only the experience of one part of a large integrated delivery network (IDN) as reported by staff, and the benefits of standardized policy and products are not being evaluated in a formal study design, the initial benefits observed are encouraging. Sanford would recommend the ZERO‑IN™ Program to other healthcare systems that are looking to improve product training and education related to Bard Medical urology products, with the objective of reducing variation in clinical practice.6 From the perspective of Sanford employees, the standardized enterprise-wide urology policy, in conjunction with the product training and staff education associated with the ZERO-IN™ Program, helped enable Sanford to improve the consistency of care provided to patients while maximizing hospital efficiencies.6 In combination, these sustainable improvements will continue to benefit both patients and the healthcare system. The value of standardization and product training has been widely acknowledged across the enterprise. As a result, the executive team will continue to evaluate other clinical initiatives that may benefit from similar initiatives.

Disclosure: This hospital experience report was sponsored by Bard Medical, a division of C. R. Bard, Inc. DB, ED, and TH are employees of Sanford Health. AH is an Associate Project Manager for Cornerstone Research Group, contracted by Bard Medical Division to conduct the interviews and write the report.

Correspondence: Erica DeBoer, Sanford Health, 1410 W 25th Street, Sioux Falls, SD, 57105-1552, [email protected]

References

1 American College of Emergency Physicians. Quality of Care and Outcomes Management Movement. Accessed at: https://www.acep.org/Clinical—Practice-Management/Quality-of-Care-and-the-Outcomes-Management-Movement/

2 Gould CV et al. (2010) Centers for Disease Control and Prevention: Guideline for prevention of catheter-associated urinary tract infections 2009. Infect Control Hosp Epidemiol 31(4):319-326.

3 Agency for Healthcare Research and Quality (2015) AHRQ Safety Program for Reducing CAUTI in Hospitals . AHRQ Pub No. 15-0073-2-EF

4 Cardinal Health (2012) The business of healthcare: optimizing your supply chain Essential Insights

5 Park KW and Dickerson C (2009) Can efficient supply management in the operating room save millions? Current Opinions in Anaesthesiology 22 242-248.

6 C. R. Bard Inc., Data on file. (2017) Sanford Hospital Experience Interviews of 14 Staff from Infection Prevention, Supply Chain Management, and Nursing conducted Dec. 19, 2016 and Jan. 9, 10, and 16, 2017 by Cornerstone Research Group.

7 Lo E, Nicolle LE, Coffin SE, Gould C, Maragakis LL et al. (2014) Strategies to Prevent Catheter-Associated Urinary Tract Infections in Acute Care Hospitals: 2014 Update. Infect Control Hosp Epidemiol 35(5):464-479

8 Zubkoff L, Neily J, King BJ, Dellefield ME, Krein S et al. (2016) Virtual Breakthrough Series, Part 1: Preventing Catheter-Associated Urinary Tract Infection and Hospital-Acquired Pressure Ulcers in the Veterans Health Administration. Jt Comm J Qual Patient Saf 42(11):485-AP2

9 Bard Medical Division, Data on file. (2015) ZERO-IN Comprehensive Clinical Solutions Brochure. BMD/TRAY/0815/0002

10 Smith F (2012) Bone products in surgery: a blueprint for standardization. AORN Journal 95 (2).

11 McKesson (2001) Achieving operating room efficiency through process integration. Healthcare Financial Management

12 Sanford Health (2017) Internal data on file. Data obtained through INFOR item master.

13 Keleekai NL, Schuster CA, Murray CL, King MA, Stahl BR et al. (2016) Improving nurses’ peripheral intravenous catheter insertion knowledge, confidence, and skills using a simulation-based blended learning program: a randomized trial. Simul Healthc 11(6): 376-384