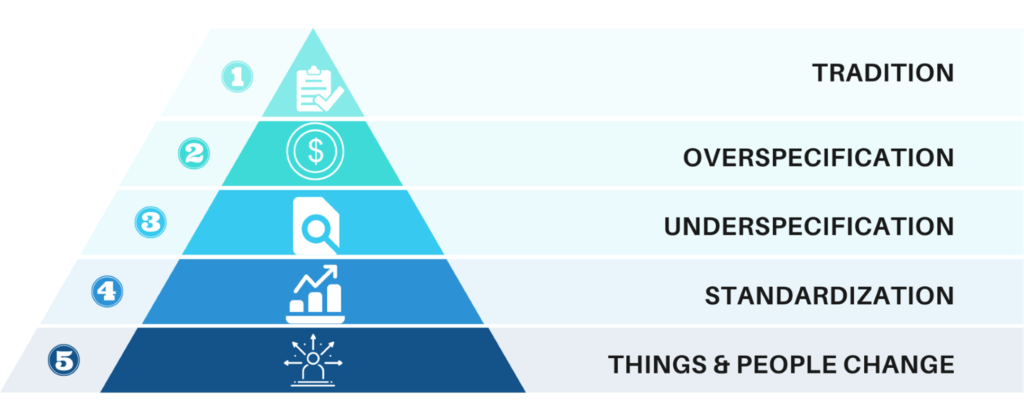

Savings Opportunities Pyramid

Every product, service, and technology should have their functional requirements or exact specifications defined by your customers, not specified by their sales representative or selected from a catalog as often happens. Because of this fact, many of the products, services, and technologies you are buying are non-conforming to requirements because of:

1. TRADITION: Customers continue to purchase a particular product, service, and technology because they “have always done it that way.” Like insisting that they need four ports on their IV catheters when there is no medical reason to do so.

2. OVERSPECIFICATION: Like tradition, customers buy products, services, and technologies that have too many components, too many features, and are too big, too small, or too robust. One of our clients had been buying patient slippers at a cost of $3.95 when a $0.99 slipper actually met their patients’ functional requirements exactly.

3. UNDERSPECIFICATION: Underspecifications include too few components, too few features, and missing functions. For example, when one of our health system clients functionally analyzed their patient garment bags, they found them to be too small at eight of their hospitals. Actually, none of their bags were big enough to hold their patients’ garments.

4. STANDARDIZATION: Standardization assumes that one size fits all required functions for all of your customers, which is never the case in the real world. A better strategy is customization, which recognizes that 80% of your customers can accept your standardized products, services, or technologies but that 20% need either a higher or lower specified product, service, or technology. In the end, customization will save you the most money.

5. THINGS CHANGE AND PEOPLE CHANGE: I could bet you that the majority of products, services, and technologies you are buying today were specified by employees who have either retired, transferred to another department, or have left your place of employment. Yet, no one has challenged that the products, services, or technologies specified are conforming to requirements today. For example, we came across a General Requisition Form that was costing our client $180,536 annually. When we performed a value analysis study on this form, we were able to re-engineer the form and correct the huge waste of the form on nursing floors because of faulty printers for a savings of $93,994 annually. That’s what happens when things change and people change, yet no one challenges why these commodities are still being purchased.

One of the secrets to saving money with value analysis is to define the functional requirements or specifications of the products, services, and technologies you are buying. Then, have annual reviews of your top 100 categories of purchase to ensure that they are still conforming to requirements. Chances are, 10% to 15% will not conform to requirements and then can be reconfigured to reduce unnecessary and unneeded costs.

| About Robert T. Yokl, Founder & Chief Value Strategist for SVAH Solutions |

|---|

| Robert T. Yokl is President and Chief Value Strategist at SVAH Solutions. He has four decades of experience as a healthcare supply chain manager and consultant, and also is the co-creator of the Clinitrack Value Analysis Software and Utilizer Clinical Utilization Management Dashboard that moves beyond price for even deeper and broader clinical supply utilization savings. Yokl is a member of Bellwether League’s Bellwether Class of 2018. https://www.SVAH-Solutions.com https://www.SavingsValidator.com |

Articles you may like:

Value Analysis: Your Purchase Costs Are Only the Tip of the Iceberg

Laying a Strong Foundation for Your Recall Management Program