Clinical supply utilization management (CSUM) is not a one-time event but instead is a fluid and ever-changing system to track everything in your supply chain using patient volume centric metrics to ascertain where savings, problems, and quality improvements are. Most organizations think of supply utilization as spend management, but it is really about consumption, overuse, waste, inefficient use, life cycle shortfalls, and feature-rich products. The fluidity of CSUM is because of the ebb and flow of the month-by-month and year-by-year healthcare supply chain spend to patient volume dynamics. It is ever changing, and a new savings opportunity pops up every month when you update your data. In essence, it is the gift that keeps giving major savings.

Why Is Clinical Supply Utilization Management the Gift that Keeps on Giving?

CSUM has been a wonderful system for me and my clients over the past 15 years since we implemented our CSUM solutions with savings on average being 5% to 11% of total supply budget. CSUM is comparable to the days when a hospital or health system finally broke down and joined a GPO, then implemented the contracts and realized millions of dollars in savings. The savings have continued for them up to this day, although they are no longer as high due to market conditions. CSUM is similar to implementing a GPO contract because most health systems are currently doing little to nothing about their CSUM enterprise-wide, so there will be huge savings right from the get-go. I remember one health system client we started working with on CSUM initiatives that saved $2 million in only four areas of opportunity. That was only four opportunities, and they had hundreds more.

Every time you update your data, whether it be monthly or quarterly, you will find as we do that something has changed and some products’ cost per metric is skyrocketing, but at least now you know this and have proof that this is happening. Every month when we update our client’s data, we find so many savings opportunities that we have to be strategic in what we recommend is a good savings opportunity at that time. You want to be in this place too and have more savings than you need so you can pick and choose the right opportunities and the right time.

Reading Between the Price and Contracting Lines

Price and standardization are undoubtedly a factor of supply utilization but at best you can maybe affect up to 20% of the total cost of a product or service, whereas with CSUM you have more of the product pie to go after – even up to as much as 100% if you eliminate a product you don’t need. It will show you that you are running too high in some areas and will put firm numbers to the actual opportunities you need to work towards to reduce costs further.

You May Have the Best Pricing in a Category but Have High Utilization Costs

Some think that if they get the best price and standardization that they don’t need to worry about things like supply utilization because they have the best pricing and thus feel that they have the best overall costs. That cannot be further from the truth because there are two simple aspects to product procurement that dispute that idea. First, you have rich products that have rich features. If you are using the Rolls Royce of any product category and only really require the Ford or Chevy model, then you are going to have higher costs on those products. If you own a BMW, you know that the maintenance costs alone, not to mention the payments, will be much higher than owning a Kia or Honda that will still get you to where you need to be and will probably have more features than that base model BMW you overpaid for. It’s the same with healthcare supply chain products, and there are hundreds of them within most categories that we need to get right.

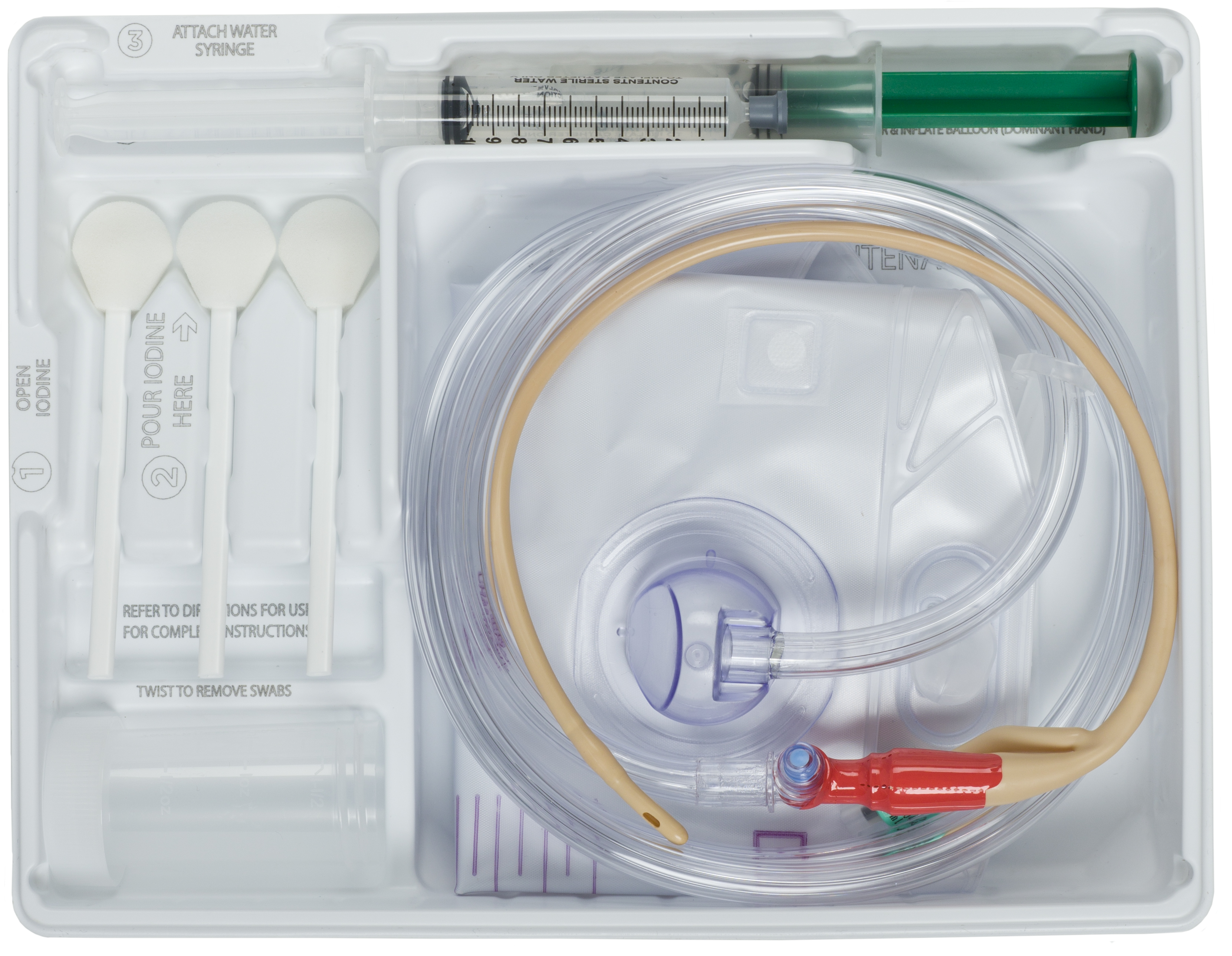

Second, which I have found most important in my 33 years of performing value analysis reviews, is the quantity of products you use. Having the best price is great, but if you are using 23% to 42% more Cath Lab Balloons (Balloon Cost Per Cath Lab Case), IV Sets (Cost Per Adjusted Patient Day), or CRM Devices (Average Cost Per Implant), then you are losing real bonafide savings by ignoring that this is happening. Wouldn’t you want to know what categories are running amuck by using real data-centric methods, key performance indicators, and multiple benchmarking methods to truly identify savings opportunities forever?

Where Does Value Analysis Fit In?

Somebody must manage the CSUM program, and we have found that your VA managers and teams are the perfect fit for this. They will require more training so that they understand the dynamics they are dealing with, but once you have that in place and get a few wins under your belt, you will be off finding savings on an ongoing basis. VA does not have cost savings reporting tools dedicated to them and let’s face it, the VA process is spot-on to drill down to the root cause and then implement solutions to achieve the next level of big savings.

Start with a Baseline and Keep Updating

There is a starting point to everything and CSUM is no different in that you need a starting point to start tracking from and measuring your peaks and valleys that will help you uncover areas of needed cost and quality improvements. I highly recommend that you utilize a database for CSUM as we have found that is the best for reporting this information out. Data will need to be cleaned and validated as well but it is not as difficult as you might think, and the big savings juice is definitely worth the squeeze. If you have any questions, reach out to me at ryokl@svahsolutions.com.

There is Always Good News with Clinical Supply Utilization Management

The good news is that you still have time to lead your organization down the CSUM road and start to capture this low-hanging fruit that has been sitting there forever because you did not realize the value of the big savings it could bring about. CSUM not only points you to big savings but also tells you where you are achieving best practice level cost and quality results which are highly valuable. These are just a few of the advantages of CSUM. Once you start your program, you will wish that you had implemented one sooner. There is no time like the present to start planning out your CSUM program.

| About Robert W. Yokl, President of SVAH Solutions |

|---|

| Robert is the President of SVAH Solutions which provides value analysis, clinical supply utilization, and savings validation tools to help healthcare organizations gain the next level of savings beyond price and standardization. https://www.SVAH-Solutions.com https://www.SavingsValidation.com |

Articles you may like:

12 Reasons Why You Should Have a Valid Benchmarking/KPI System to Point You in the Right Direction