Bruce Rippe, Chairman, CEO, Trinity Guardion

Edmond Hooker, MD, Ph.D., Trinity Guardion

Many hospital leaders don’t know that what might be hidden under the covers could be making their patients sick and costing them money. In order to prevent this, leaders must understand the current state of cleaning and disinfecting of mattresses compared to what the manufacturers’ instructions for use (MIFUs) require in order to maintain the integrity of the investment. While many hospitals have adopted more rigorous cleaning and disinfecting protocols for hospital rooms as a result of the COVID-19 pandemic, most may have not adopted advanced decontamination practices for mattresses. The status-quo is fraught with patient safety issues because it can leave residual bacteria and other microorganisms on the mattress that can be transmitted from patient to patient, leading to hospital-acquired infections (HAIs).1-4 Studies have shown that mattresses contribute to the current high rates of HAIs, but most hospitals currently aren’t aware that they are failing to meet the FDA’s disinfection guidelines. 5-7

Even before the pandemic, ECRI, a leading patient safety organization, underscored the importance of addressing hospital mattress contamination. The organization named hospital beds and mattresses as a top health hazard in 2018 and 2019.8,9 The ECRI report stated that the recommendations for cleaning and disinfecting mattresses made by many mattress manufacturers and mattress rental companies were not in accordance with FDA guidance.10 It also raised concerns about facilities’ use of non-recommended mattress cover cleaning and disinfection materials, deficient exterior inspections during terminal room cleaning, deficient inspection of support surfaces, use of covers beyond expected life, and hospitals’ protocols of one-step cleaning and disinfection (often using bleach) processes without rinsing.

This ECRI alert, combined with increasing pressures to keep patients safe and keep costs down in 2020 and beyond, is a call to action for value analysis leaders. After all, value analysis teams play a critical role in bridging the gap between executives, clinical leaders, patients, and the supply chain directors. That’s why it’s time to reimagine the crisis of this pandemic as a time of opportunity and action. Value analysis leaders have already emerged from behind-the-scenes as healthcare heroes by honoring their call to duty to choose products based on evidence and outcomes. Now, they are poised to advocate for much-needed change, ensuring both clinical efficacy and high financial value for their organizations.

Getting Informed to Keep Patients Safe

According to the most recent Healthcare-Associated Infection (HAIs) Prevalence Survey by the CDC, in 2015, U.S. acute care hospitals experienced an estimated 687,000 HAIs and 72,000 HAI-related deaths.11 In 2017, C. diff infections accounted for 235,000 HAIs, many of which are the result of cross-contamination between patients. 12 Studies also show that patients are 6 times more likely to acquire an HAI if the previous bed occupant had been infected; another key indicator that current mattress contamination practices are falling short. 13

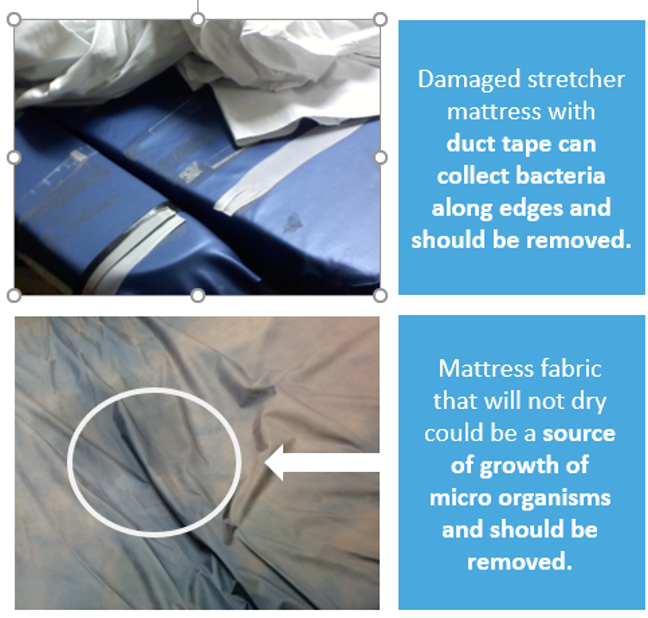

But it’s vital to understand that stronger disinfectants are not the answer. These harsh chemicals can damage mattress “skins” and mattress cores, which increases the infection risk for patients. 14 Yet, many hospitals still rely on the off-label use of disinfectants and single-step processes that are not recommended by mattress manufacturers, which results in the failure to disinfect the surface and ultimately leads to a shortened life of the beds and mattresses.

Hospitals must recognize that they must move away from the idea of using single-step processes for cleaning and disinfection. They must realize that a new process has been designed by the manufacturers specifically for the healthcare mattresses of today, as the manufacturers have moved away from vinyl (hard, non-porous surface) to polyurethane (soft, porous surface). The change in material for the surface of the mattress (the “skin”) was made in order to decrease patient pressure ulcers. The vinyl mattress surfaces were previously cleaned and disinfected with a one-step hard surface disinfectant, but polyurethane surfaces require multiple steps, as determined by the manufacturer, in order to achieve the disinfection levels recommended by the FDA and CDC. None of the currently used surface disinfectants are approved for use on soft surfaces.15 Also, none of the non-contact methods (e.g. UV light) have any FDA approved claims to kill bacteria on these soft surfaces.16

A New Best Practice with Tangible Value and ROI

A recent peer-reviewed study published in Sage Journal’s Infectious Disease Research and Treatment publication, found that using a removable, launderable bed barrier is more effective at eliminating bacteria that cause C. diff, MRSA, and E. coli than manual processes using chemical disinfectants.17 This verifiable and cost-effective method of bed and mattress disinfection is quickly becoming an industry best practice, especially in today’s COVID-19 reality as more patients begin to re-enter hospitals and resume elective procedures.

The commercial laundry process detailed in the study provides detergent, bleach, agitation, and heat. These elements allow bacteria and spores to be physically separated from the barrier surface. The chlorine works to kill residual organisms. Multiple rinse cycles allow the microorganisms to be removed from the washing machine. The use of the laundry ensures a repeatable process that takes the human element out of the equation. Hospitals, patients, and caregivers know that they have a disinfected surface for the patient every time.

“The current state of cleaning and disinfecting beds and mattresses is dangerous because it can leave residual bacteria that can be transmitted from patient to patient. However, laundering removable bed barriers provides an alternative. It eliminates issues with insufficient removal of pathogens from the patient surface,” said Ardis Hoven, MD, Professor of Medicine at the University of Kentucky and an Infectious Disease consultant to the Kentucky Department for Public Health.

Launderable bed barriers, developed by Trinity Guardion based on scientific evidence and countless research studies, meet and surpass the required disinfection guidelines.18 The first-of-its-kind bed barrier empowers hospitals to achieve superior disinfection results by leveraging a more robust, high heat laundry process to exceed the CDC guidelines and manufacturers’ recommended multi-step processes. As a result, beds and mattresses are cleaner when compared to more traditional disinfection methods, and the risk of cross-contamination is eliminated.

The final inspection process at the laundry ensures that the barrier has no tears or other damage. The use of the barrier helps hospitals to keep patients safer by reducing healthcare acquired infections and extending the life of beds and mattresses. By reducing risk and reducing infections, launderable bed barriers boost patient safety and promote high-value care.

Assessing the Financial Impact – A Business Case that Makes Itself

Keeping the status-quo is not just ineffective but incredibly costly. Beds and mattresses are typically a hospital’s fifth largest capital investment. Current processes not only leave bacteria that can be transmitted from patient to patient but also drastically reduce the life of beds, mattresses, and mattress skins. Although hospitals may be concerned about any capital outlays during these challenging financial times, investing in a new mattress decontamination approach with launderable bed barriers delivers a substantial ROI in less than one year. Even more importantly, it continues to deliver value year over year.

5 Reasons to Invest in the Launderable Bed Barrier

5 Reasons to Invest in the Launderable Bed Barrier

1. MIFU reprocessing costs are very expensive, time-consuming, and ineffective for C. diff.

2. Not adhering to MIFUs for cleaning and disinfection voids the manufacturer’s warranty.

3. Reaching the warranted life of mattresses and mattress covers has a profound positive impact on hospital budgets.

4. Reducing HAIs improves patient safety.

5. Launderable bed barriers help hospitals to keep patients safer and margins more manageable by reducing HAIs, reducing reprocessing costs, and extending the life of beds and mattresses.

Hospitals have invested millions in beds and mattresses; however, due to use of harsh chemicals, these mattresses are failing at alarming rates.19,20 This is costing the organizations millions of dollars. Failures are being caused by non-MIFU compliant cleaning and disinfection processes. That means that they fall short of reaching the expected life promised by the manufacturers and must be replaced much sooner than planned according to capital budget cycle. One real-world example from a recent mattress audit at a large academic medical center found that 60 percent of 3-year-old mattresses needed to be entirely replaced.21 An additional 40 percent of mattresses needed a new mattress skin.21

Inside of top mattress cover is DISINTEGRATED BY

DISINFECTANT use as well as fire barrier sock protecting the patient

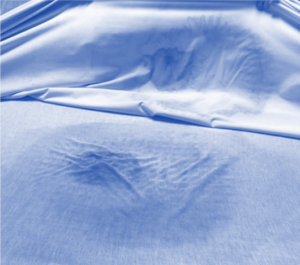

Hospitals spend countless hours and dollars on cleaning and disinfecting beds and mattresses, and yet, the time spent on one-step processes, or even following complicated MIFUs, fails to deliver meaningful results. The cost of labor, combined with the lack of efficacy of the disinfection during the status-quo approach, is ultimately both expensive and ineffective. Also, hospitals are required by manufacturer MIFUs, as well as FDA and CDC recommendations, to perform routine inspection of the mattress after each use.22-23 Unfortunately, most hospitals do not have a mattress audit inspection process for the interior and exterior. As a result, failed mattresses are common in many hospitals, exposing patients to previous patients’ bodily fluids due to fluid immersion inside the mattress.

While the use of the launderable bed barrier has an excellent ROI just based on hard cost, the complete business case also should account for soft cost savings which may not always show up on the balance sheet but matter more than ever in this era of tenuous finances. Contaminated mattresses can pile on costs when the patients lying on them develop HAIs. The launderable bed barrier, which has been shown to reduce C. diff infections by 50 percent or more, has a profound impact in decreasing these soft costs. 24,25

For example, a 40-bed medical ICU using the Trinity Guardion Soteria Bed Barriers can experience an annual savings of $125,000 thanks to the synergistic combination of decreased replacement costs of mattress skins and mattress cores, a 50% reduction in C. diff cases, and a decrease in environmental service cleaning labor and materials.

Value Analysis Leaders Call to Action

For value analysis leaders, the time is now to translate this new knowledge into action to protect patients. The time is now to turn this newly acquired knowledge about mattresses and hospital beds into major financial savings for organizations.

Bruce Rippe, Chairman, CEO

Bruce is a serial entrepreneur who was responsible for inventing Trinity Guardion’s flagship product, a hospital bed barrier designed to prevent patient infections, & guiding the development & validation of this unique product. As CEO, he oversees all operations of the company. He previously served as CEO of Romweber (Batesville, IN). With more than 30 years of experience in furniture manufacturing & product development, Bruce spent nearly 20 of those years developing patient room products for Hill-Rom & Med-Mizer. In addition to his work at Trinity Guardion, Bruce serves as board chair for the Batesville Senior Café, a developer of affordable senior housing in Southeast Indiana that offers assisted living services, & is a past board member of Margaret Mary Health. Bruce holds a BSBA in accounting from Xavier University.

Edmond Hooker, MD, DrPH, Clinical Advisor

Edmond Hooker teaches in the Department of Health Services Administration at Xavier University. He also practices emergency medicine & conducts public health research at the University of Cincinnati Hospital, & serves as their residency research director, overseeing the clinical research coordination program. Edmond has authored more than 50 articles in leading journals & published numerous book chapters. He serves as an editor & has contributed numerous chapters for eMedicine, an online clinical knowledge base. Edmond holds a BS degree from Hampden-Sydney College in Virginia & a MD from Eastern Virginia Medical School. He completed his residency training in emergency medicine at the University of Louisville, then served as an associate professor & director of resident research there from 1991–1996. He then served on the faculty at the University of Virginia. In 2007, Edmond earned his Doctorate in Public Health from the University of Kentucky, & in 2015, was promoted to professor. He has spent eight years researching infection risks associated with hospital beds & mattresses, which has led to numerous published articles & guest lectures on the topic.

References

- 1. de Andrade D, Angerami ELS, Padovani CR. A bacteriological study of hospital beds before and after disinfection with phenolic disinfectant. Rev Panam Salud Publica. 2000;7(3):179-184. doi:10.1590/s1020-49892000000300007

- Fernando FSL, Ferreira AM, Colombo TE, Rubio FG, Almeida, MTG. Fungal contamination of hospital mattresses before and following cleaning and disinfection. Acta Paul Enferm. 2013;26(5):485-491.

- Hooker EA, Allen S, Gray L, et al. A randomized trial to evaluate a launderable bed protection system for hospital beds. Antimicrob Resist Infect Control. 2012;1(27). doi:10.1186/2047-2994-1-27

- Hu H, Johani K, Gosbell IB, et al. Intensive care unit environmental surfaces are contaminated by multidrug-resistant bacteria in biofilms: combined results of conventional culture, pyrosequencing, scanning electron microscopy, and confocal laser microscopy. J Hosp Infect. 2015;91(1):35–44. doi:10.1016/j.jhin.2015.05.016

- Bousquet A, van der Mee-Marquet N, Dubost C, et al. Outbreak of CTX-M-15–producing Enterobacter cloacae associated with therapeutic beds and syphons in an intensive care unit. Am J Infect Control. 2017;45(10):1160-1164. doi:10.1016/j.ajic.2017.04.010

- Cadot L, Bruguière H, Jumas-Bilak E, et al. Extended spectrum beta-lactamase-producing Klebsiella pneumoniae outbreak reveals incubators as pathogen reservoir in neonatal care center. Eur J Pediatr. 2019;178(4):505–513. doi:10.1007/s00431-019-03323-w

- Pantel A, Richaud-Morel B, Cazaban M, Bouziges N, Sotto A, Lavigne JP. Environmental persistence of OXA-48–producing Klebsiella pneumoniae in a French intensive care unit. Am J Infect Control. 2016;44(3):366-368. doi:10.1016/j.ajic.2015.09.021

- 2019 Top 10 Health Technology Hazards: Executive Brief. ECRI Institute. https://www.ecri.org/Resources/Whitepapers_and_reports/Haz_19.pdf. Published October 2019. Accessed September 4, 2020.

- Top 10 Health Technology Hazards for 2018: Executive Brief. ECRI Institute. https://www.ecri.org/Resources/Whitepapers_and_reports/Haz_18.pdf. Published 2018. Accessed October 2, 2020.

- Reducing the Risks of Fluid Ingress and Microbiological Contamination in Bed and Stretcher Support Surfaces. ECRI Institute. https://www.ecri.org/components/HDJournal/Pages/Reducing-Fluid-Ingress-Risks-in-Bed-Support-Surfaces.aspx?tab=2# . Published May 10, 2017. Accessed September 4, 2020.

- Healthcare-associated Infections: Data Portal. cdc.gov. https://www.cdc.gov/hai/data/portal/index.html. Reviewed January 2, 2020. Accessed October 2, 2020.

- Guh AY, Mu Y, Winston LG, et al. Trends in U.S. burden of Clostridioides difficile infection and outcomes. N Engl J Med. 2020;382:1320-1330. doi:10.1056/NEJMoa1910215

- Cohen B, Liu J, Cohen AR, Larson E. Association between healthcare-associated infection and exposure to hospital roommates and previous bed occupants with the same organism. Infect Control Hosp Epidemiol. 2018;39(5):541-546. doi:10.1017/ice.2018.22

- Milnes J. The impact of cleaning chemicals on polyurethane mattress cover materials and their propensity for physical damage. Dartex Coatings Limited. http://www.dartexcoatings.com/Dartex/media/SiteImages/Applications/events/TVS-Poster-Presentation-%28-news-article-5%29.pdf. Accessed September 4, 2020.

- McGoldrick M. Soft surface sanitizing. Home Healthcare Now. 2015;33(1):52-53. https://www.homecareandhospice.com/pdfs/McGoldrick_Soft_Surface_Sanitizing.pdf. Accessed September 4, 2020.

- UV Lights and Lamps: Ultraviolet-C Radiation, Disinfection, and Coronavirus. fda.gov. https://www.fda.gov/medical-devices/coronavirus-covid-19-and-medical-devices/uv-lights-and-lamps-ultraviolet-c-radiation-disinfection-and-coronavirus. Updated August 19, 2020. Accessed September 4, 2020.

- Hooker EA, Ulrich D, Brooks D. Successful removal of Clostridioides difficilespores and pathogenic bacteria from a launderable barrier using a commercial laundry process.

Infect Dis (Auckl). 2020;13:1-6. doi:10.1177/1178633720923657 - Reprocessing Medical Devices in Health Care Settings: Validation Methods and Labeling. fda.gov. https://www.fda.gov/media/80265/download. Published March 17, 2015. Updated June 9, 2017. Accessed September 11, 2020.

- Bradbury SL, Mack D, Crofts T, Ellison RT. Potential bloodborne pathogen exposure from occult mattress damage. Am J Infect Control. 2014;42(4):421-422. doi:10.1016/j.ajic.2013.10.011

- Marks B, de Haas E, Abboud T, Lam I, Datta IN. Uncovering the rates of damaged patient bed and stretcher mattresses in Canadian acute care hospitals. Can J Infect Control. 2018;33(3):171-175.

- Trinity Guardion Mattress Audit. 2020.

- Stryker® Operations/Maintenance Manual: IsoAir™ REV 4. Stryker. https://techweb.stryker.com/Support_Surfaces/2940/AO-SM-70-C_EN_Canada_Rev4.00.pdf. Published December 2015. Accessed September 4, 2020.

- Covers for Hospital Bed Mattresses: Learn How to Keep Them Safe. fda.gov. https://www.fda.gov/medical-devices/hospital-beds/covers-hospital-bed-mattresses-learn-how-keep-them-safe. Published November 20, 2017. Accessed September 4, 2020.

- Hooker EA, Bochan M, Reiff TT, Blackwell C, Webb KW, Hart KW. Decreasing Clostridium difficile health care–associated infections through use of a launderable mattress cover.

Am J Infect Control. 2015;43(12):1326–1330. doi:10.1016/j.ajic.2015.07.002 - Hooker EA, Mallow PJ, McKinney C, Gnoni ML, Fernandez Gonzales F. Use of a launderable bed barrier and antibiotic stewardship to decrease hospital onset Clostridioides difficile infections in an acute care hospital: A retrospective pre/post case study. JHEOR. 2019;6(3):196-202. doi:10.36469/001c.11149