By Robert W. Yokl, Sr. VP, Supply Chain & Value Analysis — SVAH Solutions

Ninety-five percent of hospitals and health systems have no way of knowing where their clinical supply utilization savings opportunities are right now and thus are not worried about these major savings opportunities because they are out of sight and out of mind. That does not mean that these savings opportunities are not there. They just don’t have a mechanism to report them out meaningfully and given the challenging times, probably don’t want to be bothered with going after new savings opportunities anyway. But there are those progressive supply chain leaders who do recognize that these savings are real, and their CFOs are looking for the next big thing when it comes to major savings. That next big thing in savings is savings beyond price or what we call clinical supply utilization management (CSUM), and it will blow your mind how much savings is hidden from your view.

Is Not Knowing What You Don’t Know Good for Your Supply Chain Budget?

Price savings is not a complex animal today as we have group purchasing organizations that have set the path for the tier-based opportunities that most healthcare organizations purchase from. And yes, there is custom contracting, but most vendors/manufacturers tend to extend their custom pricing from the pricing they give to the GPOs anyhow, so the logic and savings is all straight forward. This price savings method follows a standard model that has come to a high level of maturity over the past 10-15 years.

What this maturity means to healthcare organizations around the country is that the savings is not what it once was when you used to save 5% to 10% in overall supply chain budget every year. That was great while it lasted. The reality is that, as our studies have shown, hospitals and health systems are lucky to save between 1% to 2% of overall supply chain budget in any given year. What does this mean? Healthcare organizations are proficient in the price game but now need to move on to the next big saving area and there is only one place to go – CSUM.

Imagine the Next Big Savings Area That You Could Spend the Next 5-8 Years Achieving with Great Success

To paint a picture for you, like the now mature price aspect of our marketplace, success did not come overnight with price. It took the better part of 10-20 years of the group purchasing organizations making their contracts better and better for health systems across the country. CSUM is no different. The potential is 7% to 15% new savings opportunities from your total supply chain budget, but the savings will not just happen overnight. Rest assured, the great news is that some savings can happen overnight when you start to put together your CSUM program and associated reporting. This is because there will be some glaring areas that will pop up right away and you can get immediate wins with big savings. The best part about these savings is that you don’t have to wait a year or two until the contract comes due to do anything about these. Most CSUM opportunities are contract neutral. You can save big within your current GPO and/or custom contract portfolios.

To Achieve the Next Big Savings in CSUM, You Must Assess Where You Are Now

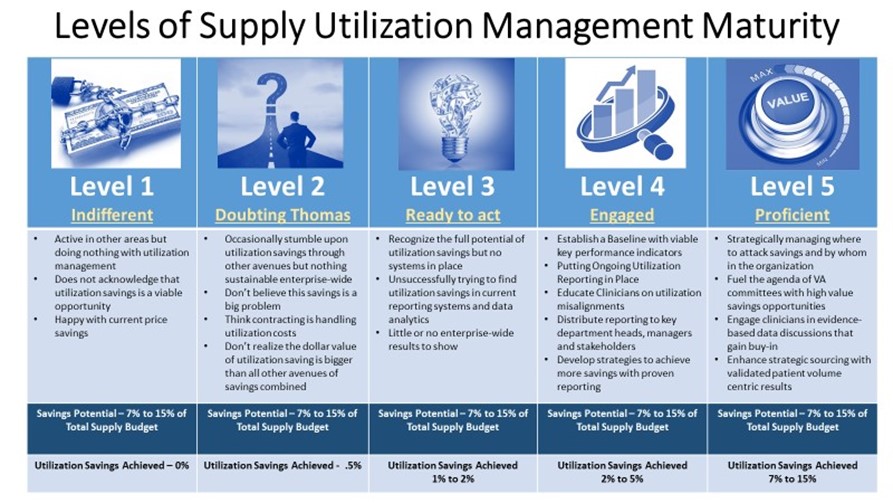

In order to assess where you are now, you must have a guide (Figure 1) to show you all the different maturity levels of clinical supply utilization management as well as help you set goals for where your program should move next.

Figure 1: Supply Utilization Management Maturity – Assessing Where You Stand

Most supply chain organizations tend to bump into or fumble upon one or two of these major savings from time to time and are at first embarrassed that these major dollar increases have been going on right under their noses for so long without being discovered. What if you had a mechanism in place in your supply chain organization that would alert you and give you a strategic vision on which supply utilization areas you need to focus your value analysis and supply chain departments on? As the adage goes, “Knowledge is power, and knowing where all of your supply utilization savings opportunities are (big and small) is extremely powerful.”

In Figure 1, you will notice that the savings potential is the same throughout all the maturity levels (7% to 15% of overall supply chain budget for supply utilization) but your results depend on your maturity level of the program you have in place. The time has come to realize that your value analysis team, supply chain analysts, and contract managers are not engaging in utilization management in a formal fashion, if at all. Yet, they may feel that this new big thing, CSUM, which is a buzz word in our industry, is part of their scope of work. I would hope they would feel that way. Let’s face facts, they don’t have the tools, time, or training to create and maintain a sophisticated and strategic CSUM program today.

Here are the Next Steps to Improve Your Savings Beyond Price Exponentially Today, Next Quarter, and for Years to Come

- Become a Believer: The biggest challenge I find with hospitals and health systems today is that they just don’t believe any substantial savings can come from supply utilization management. When I work with large hospitals and health systems, I normally have to give a number of examples or sometimes cue up a long list of savings that prove that these savings are real. That’s okay because leadership is now opening their minds to this new modality of savings. Once you start to understand that there will be significant savings opportunities in many of your supply categories regardless of how good your prices are, you can then address each and every one of these strategically.

- Data, Benchmarking, and Year-Over-Year Analysis Drives the CSUM Process: Many supply chain leaders think that their contracts or value analysis teams will somehow find all the savings beyond price. CSUM is constantly changing, and you have to have continual monitoring in order to find these savings. If you don’t have reports that are showing you where you stand on each major and minor product category (e.g., CSUM is good, needs work or urgent attention), how else could you speculate about CSUM?

- The Ultimate in Clinical Integration into Supply Chain: The new goal for supply chain leaders is to integrate clinical expertise into the supply chain process, and there is no better way to engage clinicians than to review their utilization of products, services, and technologies. There is no room for clinicians to engage in the pricing or contracting process, but when shown a report on their utilization of major product(s) you can engage in the nuances of use patterns, policies, and procedures to uncover the hidden savings beyond price. Clinicians don’t want to be bogged down with price but they can tell you why they are using the new/expensive absorbable sheets of surgical mesh or extra reloads for their endomechanical staplers. Remember, evidence is data!

- Lastly, Start Your Program Now: We have been preaching about CSUM for the past 10 years and our clients who have adopted CSUM have reaped the benefits over that time in a big way. They still have savings opportunities to manage and control better, but the utilization misalignments have been knocked down to only the newest occurrences of which they always find new savings. The key takeaway here is that you have to start a CSUM program to find out where your savings opportunities are to then strategically attack them to gain results.

I cannot tell you how many times over the past year that CFOs and even a CEO from time to time are sitting in on their value analysis team meetings to hear about the latest savings opportunities that they so desperately want now. They are looking for their supply chain leaders to find that next level of major savings to alleviate the pressure on their organization’s bottom line due to the pandemic circumstances. The biggest and best savings are sitting virtually untapped at 95% of healthcare organizations throughout the country. It is now time to put your organization into the top 5% and gain the upper hand in savings beyond price!

| About Robert W. Yokl, Sr. VP of Value Analysis & Supply Chain Solutions |

|---|

| Robert is the Program Leader for SVAH Solutions that provides value analysis, clinical supply utilization, and savings validation tools to help organizations to gain the next level of savings beyond price and standardization. https://www.SVAH-Solutions.com https://www.SavingsValidation.com |

Articles you may like:

Where are the Next Major Supply Chain Savings Going to Come from in 2021 and Beyond?